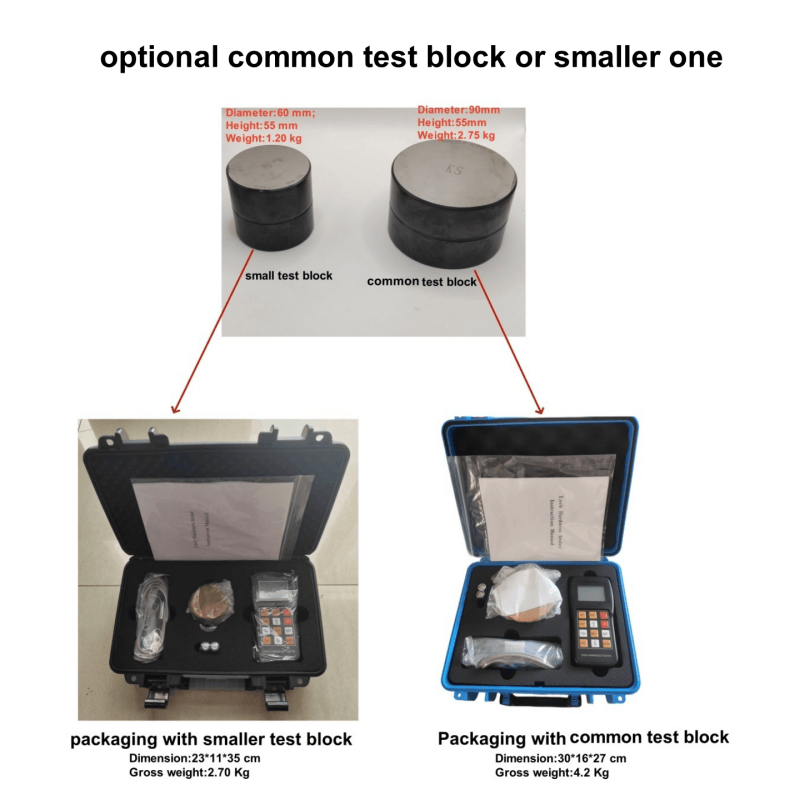

Model No.: LXH-150(with 2.75 Kg common test block)/LXH-150A (with 1.20 Kg smaller test block)

Features:

1. LCD display with backlight;

2. Capable of measurement for multiple metal materials and user- friendly;

3. Material of "cast steel" is added; HB values can be read out directly when D/DC impact device is used to measure "cast steel" work piece;

4. Compatible with 7 type impact devices. When changing impact device, the type can be identified automatically and not need to recalibrate;

5. Various direction measurement and the direction can be auto recognized;

6. Multiple common hardness scales conversion(HV,HB,HRC,HRB,HRA,HS);

7. Max 600 data can be stored including inforamtion of value,average,impact direction,scale,impact times,date,etc;

8. A professional computer analysis software to process the test data;

9. Alarm function and the upper and lower limits can be preset;

10. Optional common test block(2.75 Kg) or small test block(1.20 Kg);

Overview and application

This portable leeb hardness tester is produced with outstanding control chip and with outstanding impact device, which makes the metal hardness measurement smart, accurate, quick and without damage. The meter is compatible with 7 types impact devices and the type can be identified automatically and no need to recalibrate. Multiple common hardness scales (HL,HV,HB,HS,HRB,HRC,etc) are available and the scales is switchable. What’s more, a analysis software is developed to deal with the tested data.

The metal hardness meter can be used to measure the hardness of common metal materials. Thus, this durometer is widely applied in the field of mold, heat treatment, machining, pressure vessel, auto parts, aerospace and other industries.

Technical data

Accuracy and technical data for different impact devices

|

No. |

Type of Impact device |

Standard test block |

Indication error |

Indication repeatability |

|

1 |

D |

760±30HLD 530±40HLD |

±6 HLD ±10 HLD |

6 HLD 10 HLD |

|

2 |

DC |

760±30HLDC 530±40HLDC |

±6 HLDC ±10 HLDC |

6 HLD 10 HLD |

|

3 |

DL |

878±30HLDL 736±40HLDL |

±12 HLDL |

12 HLDL |

|

4 |

D+15 |

766±30HLD+15 544±40HLD+15 |

±12 HLD+15 |

12 HLD+15 |

|

5 |

G |

590±40HLG 500±40HLG |

±12 HLG |

12 HLG |

|

6 |

E |

725±30HLE 508±40HLE |

±12 HLE |

12 HLE |

|

7 |

C |

822±30HLC 590±40HLC |

±12 HLC |

12 HLC |

Basic technical data

|

measurement range: |

(170 ~ 960) HLD; (17.9-69.5) HRC; (19-683) HB; (80-1042) HV; (30.6-102.6) HS; (13.5-101.7) HRB |

|

Precision |

±6HLD |

|

hardness system: |

Richter (HL), Brinell (HB), Rockwell B (HRB), Rockwell C (HRC), Vickers (HV), shore (HS) |

|

measurement direction: |

360°(down, inclined down, level, inclined up and up) |

|

display |

Backlight LCD,128*64 matrix LCD |

|

data storage: |

up to 48~600 groups (impact times 32 ~ 1)) |

|

working voltage: |

2*1.5V (two AA alkaline batteries) |

|

Working time: |

Stand by more than 100 hours without backlight |

|

Communication interface |

USB |

|

Standard Impact Device |

D type |

|

Optional impact device |

D/C/DC/D+15/DL/G |

|

Tested material |

steel and cast steel, alloy tool steel, cast aluminum alloy,gray cast iron, nodular cast iron,stainless steel, copper zinc alloy (brass), copper tin alloy (bronze), pure copper |

Images description

Accuracy and technical data for different impact devices

|

No. |

Type of Impact device |

Standard test block |

Indication error |

Indication repeatability |

|

1 |

D |

760±30HLD 530±40HLD |

±6 HLD ±10 HLD |

6 HLD 10 HLD |

|

2 |

DC |

760±30HLDC 530±40HLDC |

±6 HLDC ±10 HLDC |

6 HLD 10 HLD |

|

3 |

DL |

878±30HLDL 736±40HLDL |

±12 HLDL |

12 HLDL |

|

4 |

D+15 |

766±30HLD+15 544±40HLD+15 |

±12 HLD+15 |

12 HLD+15 |

|

5 |

G |

590±40HLG 500±40HLG |

±12 HLG |

12 HLG |

|

6 |

E |

725±30HLE 508±40HLE |

±12 HLE |

12 HLE |

|

7 |

C |

822±30HLC 590±40HLC |

±12 HLC |

12 HLC |

Basic technical data

|

measurement range: |

(170 ~ 960) HLD; (17.9-69.5) HRC; (19-683) HB; (80-1042) HV; (30.6-102.6) HS; (13.5-101.7) HRB |

|

Precision |

±6HLD |

|

hardness system: |

Richter (HL), Brinell (HB), Rockwell B (HRB), Rockwell C (HRC), Vickers (HV), shore (HS) |

|

measurement direction: |

360°(down, inclined down, level, inclined up and up) |

|

display |

Backlight LCD,128*64 matrix LCD |

|

data storage: |

up to 48~600 groups (impact times 32 ~ 1)) |

|

working voltage: |

2*1.5V (two AA alkaline batteries) |

|

Working time: |

Stand by more than 100 hours without backlight |

|

Communication interface |

USB |

|

Standard Impact Device |

D type |

|

Optional impact device |

D/C/DC/D+15/DL/G |

|

Tested material |

steel and cast steel, alloy tool steel, cast aluminum alloy,gray cast iron, nodular cast iron,stainless steel, copper zinc alloy (brass), copper tin alloy (bronze), pure copper |