Features

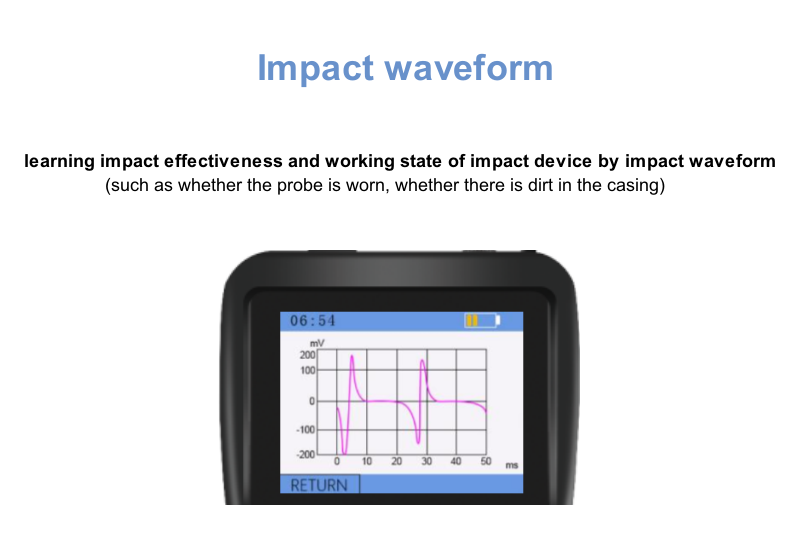

1. Impact waveform make you know effectiveness of testing and working state of impact device.

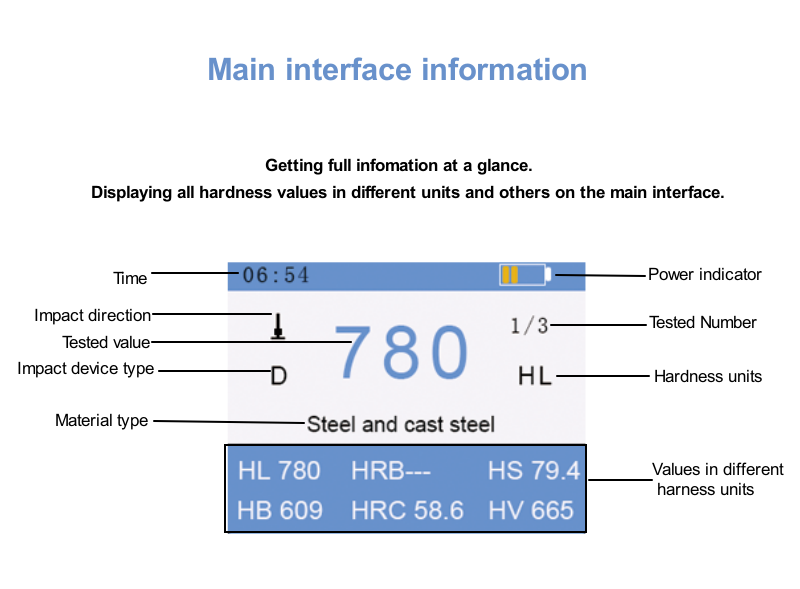

2. Getting full infomations at a glance. Showing all hardness values in different units and others on main interface.

3. Large color screen.

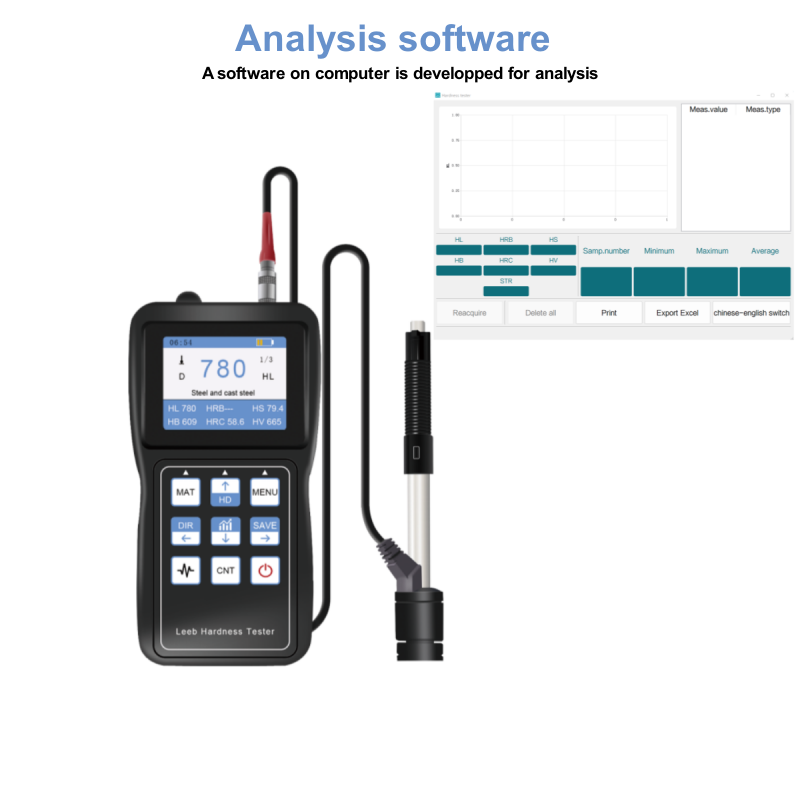

4. A computer analysis software to process the test data.

5. Bluetooth function, you can equip a Bluetooth printer specially.

6. Compatible with 7 type impact devices and all of them can be identified automatically.

7. 360° direction measurement.

8. High reliability and suitable for harsh operating environment.

Overview and application

This digital leeb hardness tester is with color screen and detachable impact device. It adopts Cortex-M0 core high-performance ARM processor as the main control chip and is equipped with outstanding impact device, which makes the measurement smart, accurate, quick and without damage. It can be used to measure the hardness of common metal materials. Thus, this digital hardness tester is widely applied in the field of mold, heat treatment, machining, pressure vessel, auto parts,aerospace and other industries.

The impact waveform is applied to this digital leeb hardness tester to make you know the working state of impact device. What’s more, A computer software is developed to process the test data, the screen shows all the values in different unit at same time and you can equip this tester with a Bluetooth printer. All of these make the metal hardness tester different.

Image description

Different impact devices information

No.

Impact device

Type

Standard Hardness Test Block

Accuracy

(Indication error)

Indication repeatability

1

D

760±30HLD

530±40HLD

±6 HLD

±10 HLD

6 HLD

10 HLD

2

DC

760±30HLDC

530±40HLDC

±6 HLDC

±10 HLDC

6 HLD

10 HLD

3

DL

878±30HLDL

736±40HLDL

±12 HLDL

12 HLDL

4

D+15

766±30HLD+15

544±40HLD+15

±12 HLD+15

12 HLD+15

5

G

590±40HLG

500±40HLG

±12 HLG

12 HLG

6

E

725±30HLE

508±40HLE

±12 HLE

12 HLE

7

C

822±30HLC

590±40HLC

±12 HLC

12 HLC

Parameters table

|

measurement range: |

170 ~ 960 HLD |

|

hardness system: |

Richter (HL), Brinell (HB), Rockwell B (HRB), Rockwell C (HRC), Vickers (HV), shore (HS) |

|

measurement direction: |

support vertical downward, oblique downward, horizontal, oblique upward and vertical upward |

|

measuring materials: |

steel and cast steel, alloy tool steel, cast aluminum alloy,gray cast iron, nodular cast iron, stainless steel, copper zinc alloy (brass), copper tin alloy (bronze), pure copper |

|

display |

color screen |

|

data storage: |

up to 100 groups (impact times 32 ~ 1)) |

|

working voltage: |

3V (two AA size alkaline batteries in series) |

|

continuous working time: |

Low brightness for about 15 hours.;High brightness for about 7 hours |

|

communication interface standard: |

USB |